Tradução e análise de palavras por inteligência artificial ChatGPT

Nesta página você pode obter uma análise detalhada de uma palavra ou frase, produzida usando a melhor tecnologia de inteligência artificial até o momento:

- como a palavra é usada

- frequência de uso

- é usado com mais frequência na fala oral ou escrita

- opções de tradução de palavras

- exemplos de uso (várias frases com tradução)

- etimologia

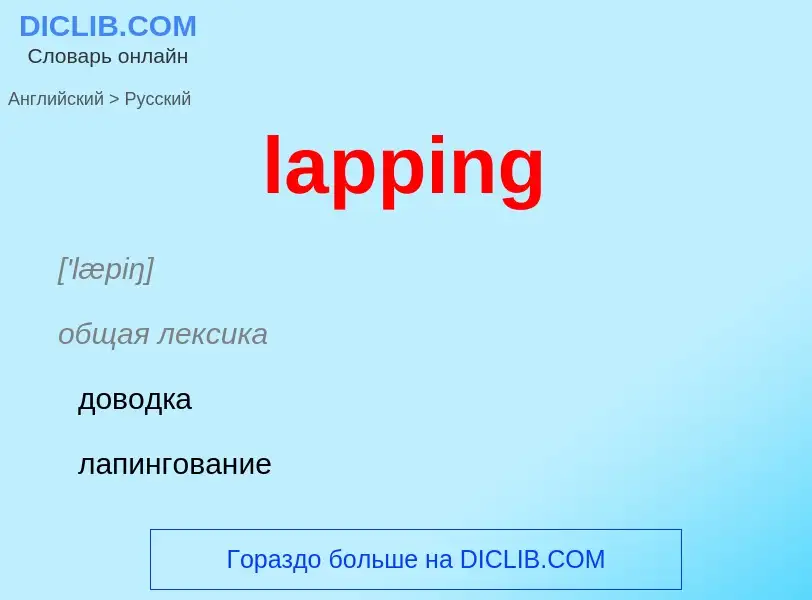

lapping - tradução para russo

['læpiŋ]

общая лексика

доводка

лапингование

лаппингование

накладывание

нахлесточный

нахлестывание

перекрывание

перекрытие

полировка

притирание

притирка

притирочный

пришлифовывание

бухгалтерский учет

"перекрытие" (техника мошенничества в бухгалтерском учете, состоящая в воровстве поступающих от клиента денег и покрытии недостачи следующим поступлением (т. е. кассир забирает себе деньги, переданные первым клиентом, а сумму недостачи покрывает денежными поступлениями от второго клиента, сумму недостачи по второму клиенту - денежными поступлениями от третьего клиента и т. д.; обычно кассир надеется вернуть деньги до того, как факт кражи будет обнаружен))

строительное дело

соединение внахлёстку

нахлёстка

наклейка (полотнищ обоев) внахлёстку

синоним

существительное

['læpiŋ]

техника

нахлёстывание

напуск

сбегание (приводного ремня)

полировка

притирка

доводка

Definição

Wikipédia

Lapping is a machining process in which two surfaces are rubbed together with an abrasive between them, by hand movement or using a machine.

Lapping often follows other subtractive processes with more aggressive material removal as a first step, such as milling and/or grinding.

Lapping can take two forms. The first type of lapping (traditionally often called grinding), involves rubbing a brittle material such as glass against a surface such as iron or glass itself (also known as the "lap" or grinding tool) with an abrasive such as aluminum oxide, jeweller's rouge, optician's rouge, emery, silicon carbide, diamond, etc., between them. This produces microscopic conchoidal fractures as the abrasive rolls about between the two surfaces and removes material from both.

The other form of lapping involves a softer material such as pitch or a ceramic for the lap, which is "charged" with the abrasive. The lap is then used to cut a harder material—the workpiece. The abrasive embeds within the softer material, which holds it and permits it to score across and cut the harder material. Taken to a finer limit, this will produce a polished surface such as with a polishing cloth on an automobile, or a polishing cloth or polishing pitch upon glass or steel.

Taken to the ultimate limit, with the aid of accurate interferometry and specialized polishing machines or skilled hand polishing, lensmakers can produce surfaces that are flat to better than 30 nanometers. This is one twentieth of the wavelength of light from the commonly used 632.8 nm helium neon laser light source. Surfaces this flat can be molecularly bonded (optically contacted) by bringing them together under the right conditions. (This is not the same as the wringing effect of Johansson blocks, although it is similar).